In the realm of mechanical engineering, innovation knows no bounds. Among the many ingenious inventions that power industries, the Scotch & Yoke actuator stands as a testament to human creativity and problem-solving. This article dives into the mechanics, functionality, and applications of the Scotch & Yoke actuator, shedding light on its pivotal role in precision control and automation.

The Scotch & Yoke Actuator: An Overview

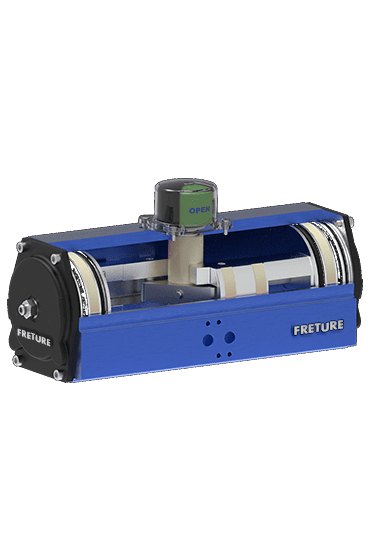

The Scotch & Yoke actuator is a mechanical device designed to convert rotary motion into linear motion through a unique and elegant mechanism. It derives its name from its distinctive components – the Scotch yoke and the sliding block or slider. This actuator has been a trusted workhorse in industries that require linear motion control with high accuracy and reliability.

|

| Pneumatic Rack & Pinion Actuator manufacturer in Mumbai |

Mechanics and Operation

The heart of the Scotch & Yoke actuator lies in the Scotch yoke mechanism, which translates the circular motion of a rotary input into linear motion. The yoke itself is a mechanism shaped like the letter "Y," with one end connected to the rotating input and the other end attached to a slider. As the input rotates, the yoke moves in a reciprocating manner, pushing and pulling the slider along a straight path.

This simple yet effective mechanism ensures smooth and precise linear motion. The key to its accuracy lies in the relationship between the radius of the yoke arm and the input angle – a fundamental principle that governs its operation.

Applications Across Industries

The Scotch & Yoke actuator finds applications in a diverse range of industries, contributing to efficient and controlled motion in various systems:

Valve Control: One of the primary applications of Scotch & Yoke actuators is in valve control systems. They are used to operate control valves, regulating the flow of fluids in pipelines, process industries, and oil and gas installations. The robust and reliable nature of these actuators makes them ideal for critical valve control tasks.

Industrial Automation: In industrial settings, Scotch & Yoke actuators play a crucial role in automating processes such as material handling, packaging, and conveyor systems. Their precision and repeatability ensure consistent performance and increased productivity.

Energy and Power Generation: These actuators are utilized in power plants to control dampers, louvers, and other mechanisms that require linear motion. Their ability to handle heavy loads and provide precise control makes them essential in energy production and distribution.

Marine and Offshore: Scotch & Yoke actuators are found in marine applications, including shipboard systems, offshore platforms, and underwater equipment. Their reliability and resistance to harsh environments make them well-suited for these demanding settings.

Advantages and Future Innovations

The Scotch & Yoke actuator offers several advantages, including high mechanical efficiency, simple design, and reliable operation. Its inherent symmetry minimizes side loads, reducing wear and enhancing longevity. Furthermore, its compact size and robustness make it suitable for installations with space constraints.

As technology advances, innovations in materials and manufacturing techniques are likely to further enhance the performance and capabilities of Scotch & Yoke actuators. Integration with digital control systems, sensors, and smart technologies could lead to more sophisticated and adaptable solutions.

The Scotch & Yoke actuator is a remarkable example of how mechanical ingenuity can shape the course of industries. From regulating fluid flows to powering automated processes, this unassuming yet highly effective mechanism has left an indelible mark on precision control and automation. As technology continues to evolve, the Scotch & Yoke actuator remains a timeless embodiment of engineering excellence, demonstrating that even in the digital age, elegant mechanical solutions continue to drive progress.

No comments:

Post a Comment