What is a Pneumatic Rack & Pinion Actuator?

A pneumatic rack and pinion actuator is a device used to convert compressed air energy into linear or rotary motion. It operates through a rack and pinion mechanism, where compressed air drives the pinion gear, which in turn moves the connected rack. This actuator is widely employed in various industrial applications for its efficiency, reliability, and ability to provide precise control over valve operations.

Features of Pneumatic Rack & Pinion Actuators

High Efficiency: These actuators are designed to provide rapid response times and high torque output, making them suitable for various industrial applications where quick actuation is essential.

Compact Design: The compact design allows for easy installation in confined spaces, enabling flexibility in system design and layout.

Durability: Constructed with high-quality materials, pneumatic rack and pinion actuators are resistant to wear and tear, ensuring long-lasting performance even in demanding environments.

Easy Maintenance: The straightforward design of these actuators facilitates easy maintenance and servicing, minimizing downtime and operational costs.

Adjustable Speed Control: These actuators allow for the adjustment of speed and torque, providing precise control over the actuation process. This feature is particularly beneficial in applications that require fine-tuning.

Safe Operation: Pneumatic actuators are inherently safe to use in hazardous environments as they do not require electrical connections, reducing the risk of sparks or explosions.

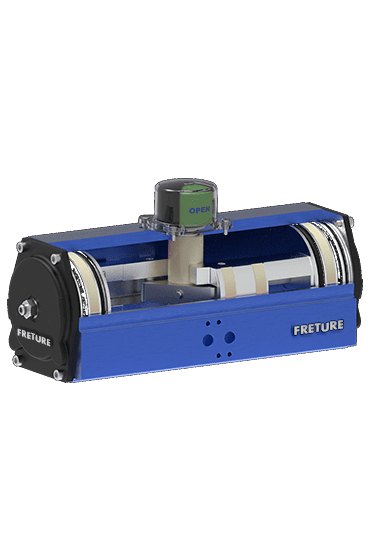

|

| Pneumatic rack and pinion actuators |

Usage of Pneumatic Rack & Pinion Actuators

Pneumatic rack and pinion actuators find applications in various industries, including:

Oil and Gas: They are used to operate valves in pipelines and processing equipment, ensuring the safe and efficient flow of materials.

Water Treatment: These actuators control the flow of water in treatment plants, helping maintain optimal operational conditions.

Chemical Processing: In chemical plants, they regulate valves to manage the flow of reactive substances, enhancing process safety.

Manufacturing: Pneumatic actuators are employed in automated production lines to control the movement of machinery and equipment.

Power Generation: They are used to operate dampers and valves in power plants, contributing to efficient energy production.

Material of Construction (MOC) Specifications

Pneumatic rack and pinion actuators are typically constructed from high-grade materials to ensure durability and reliability. Common materials include:

- Aluminum Alloy: Lightweight and corrosion-resistant, often used for the actuator housing.

- Stainless Steel: Used for components exposed to harsh environments, providing enhanced resistance to corrosion and wear.

- Nitrile Rubber or PTFE: Used for seals and gaskets to ensure leak-free operation.

Why Choose Freture Techno Pvt. Ltd. for Pneumatic Rack & Pinion Actuators?

Freture Techno Pvt. Ltd. is recognized as a leading pneumatic rack and pinion actuators manufacturer in Mumbai, India. With a commitment to quality and innovation, the company utilizes advanced manufacturing techniques and high-quality materials to produce reliable and efficient actuators. The expertise in design and engineering ensures that all products meet stringent industry standards, providing customers with solutions that enhance operational efficiency. By choosing Freture Techno Pvt. Ltd., customers can trust in the durability and performance of their pneumatic rack and pinion actuators, tailored to meet the specific needs of various industries.

No comments:

Post a Comment