Industrial linear actuators are essential components used in a wide range of applications to convert rotational motion into linear motion. From automation in manufacturing to precise positioning systems in the healthcare and automotive industries, these devices provide the accuracy and power needed to move heavy loads smoothly and efficiently. In this article, we will explore how industrial linear actuators work, their key advantages, and why they are critical to modern industry.

How Industrial Linear Actuators Work

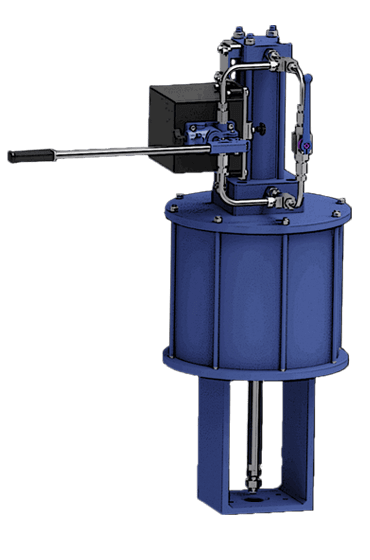

At their core, industrial linear actuators operate by converting energy (typically electrical, hydraulic, or pneumatic) into linear motion. This is achieved through a motor that drives a screw, belt, or hydraulic cylinder, depending on the type of actuator. The two most common mechanisms are:

Screw Mechanism: Linear actuators using screw mechanisms often operate based on a lead screw or ball screw principle. The motor’s rotational energy turns the screw, which moves a nut attached to the load in a linear direction. This method is widely known for its accuracy and is frequently used in applications requiring precise control.

Belt or Chain Mechanism: In this type, the motor moves a belt or chain to shift the load in a linear path. These actuators are typically employed in scenarios where speed is more critical than precision, such as conveyor systems.

Hydraulic and Pneumatic Actuators: For heavy-duty applications, hydraulic and pneumatic actuators are preferred. These systems utilize pressurized fluids (hydraulics) or compressed air (pneumatics) to push or pull a piston, which, in turn, moves the load. These types are commonly used in industries such as construction, where powerful force is needed.

|

| https://www.freture.com/valve-automation-actuator/industrial-linear-actuator/ |

Key Components of Linear Actuators

While the working mechanism may differ, all industrial linear actuators typically have three key components:

- Motor: Responsible for generating the rotational force required to drive the actuator.

- Drive Mechanism: This converts the motor’s rotational motion into linear motion. As mentioned, this can be a lead screw, belt, or hydraulic cylinder, depending on the design.

- Control System: Most modern actuators feature built-in control systems, allowing for precise movement, speed control, and even feedback mechanisms for accuracy.

Advantages of Industrial Linear Actuators

The versatility and reliability of industrial linear actuators have made them indispensable in many industries. Below are some of the core advantages they offer:

Precision and Accuracy: One of the primary advantages of industrial linear actuators is their ability to provide high levels of precision and repeatability. This is particularly important in sectors such as manufacturing, healthcare, and aerospace, where exact positioning is essential for safety and operational efficiency. Linear actuators allow machines and equipment to move loads with millimeter-level accuracy, ensuring consistent and reliable performance.

Flexibility in Application: Industrial linear actuators are highly customizable, with various models available to suit specific industrial requirements. From handling lightweight loads to moving massive equipment in harsh conditions, they offer unparalleled versatility. Electric linear actuators, for instance, can be programmed for different motion profiles, speeds, and torque levels, making them ideal for complex automation systems.

High Load Capacity: Depending on the type, industrial linear actuators can handle significant loads. Hydraulic actuators, in particular, can deliver substantial force, making them suitable for heavy-duty applications in industries such as mining, construction, and manufacturing. Additionally, ball screw-driven actuators can manage high loads while maintaining precision.

Energy Efficiency: Electric linear actuators are known for their energy efficiency, especially compared to hydraulic or pneumatic systems. These actuators only consume power when movement is needed, making them more efficient and environmentally friendly. This contributes to lower operating costs and improved energy savings for industrial applications.

Durability and Low Maintenance: Built for industrial environments, linear actuators are designed to withstand heavy use, extreme temperatures, and exposure to corrosive materials. Most industrial actuators are made from robust materials like stainless steel or aluminum, offering high durability. Furthermore, linear actuators have fewer moving parts than other mechanisms, such as rotary systems, resulting in reduced wear and tear and lower maintenance requirements.

Automation and Integration: Industrial linear actuators play a crucial role in automation. They can easily be integrated into automated systems using sensors, controllers, and feedback mechanisms. This enables industries to implement precise, repeatable processes that require minimal human intervention, improving productivity and reducing the likelihood of errors.

Applications in Various Industries

The advantages mentioned above make industrial linear actuators ideal for several critical industries. Some examples of where they are frequently used include:

- Manufacturing: For automating processes such as assembly lines, packaging, and CNC machinery.

- Healthcare: In hospital beds, medical devices, and rehabilitation equipment that require precise movement.

- Automotive: In automated assembly, robotic arms, and ergonomic tools.

- Aerospace: For controlling flaps, landing gear, and other critical components in aircraft.

- Renewable Energy: In solar panel tracking systems, ensuring optimal positioning for energy generation.

Freture Techno Pvt. Ltd.: Leading Manufacturer of Industrial Linear Actuators in Mumbai, India

When it comes to high-performance industrial linear actuators, Freture Techno Pvt. Ltd. stands as a leading manufacturer in Mumbai, India. With a strong focus on quality, precision engineering, and innovation, Freture Techno provides a wide range of linear actuators designed to meet the rigorous demands of modern industries. Whether you need solutions for automation, precision control, or heavy-duty applications, Freture Techno offers products tailored to your specific needs.

Their commitment to excellence and customer satisfaction has made them a trusted partner in the industrial automation landscape, providing efficient, reliable, and cost-effective solutions for clients across diverse sectors.

In conclusion, industrial linear actuators play a vital role in improving the efficiency, accuracy, and productivity of industrial operations. As industries continue to advance, the demand for robust and precise linear actuators will only grow, with companies like Freture Techno Pvt. Ltd. leading the way in providing cutting-edge solutions.