A limit switch box is an essential accessory for pneumatic actuators, playing a crucial role in monitoring valve position and controlling automated systems. These devices are widely used in industries such as oil and gas, chemical processing, water treatment, and power generation, where precision and reliability are vital. Understanding the purpose, functionality, and benefits of a limit switch box for pneumatic actuators allows industries to make informed decisions when it comes to automation and process control.

Understanding the Role of a Limit Switch Box

A limit switch box is designed to provide feedback on the position of a valve by signaling whether it is fully open, fully closed, or in an intermediate position. When installed on a pneumatic actuator, it helps to monitor and control the actuator's movement by sending an electrical signal to the control system, indicating the valve's status. These signals enable operators to maintain optimal process conditions, enhance safety measures, and detect faults or issues with the actuator's movement promptly.

|

| Limit Switch Box |

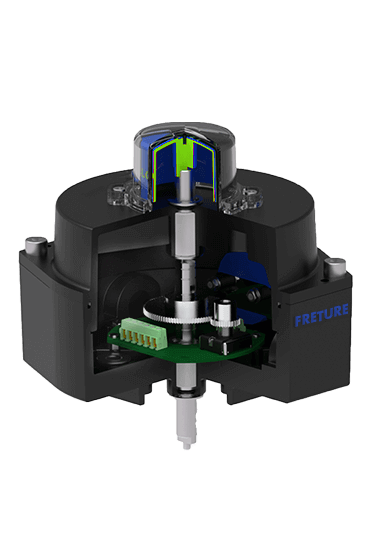

The limit switch box achieves its purpose through mechanical switches or proximity sensors. These components detect the physical position of the actuator’s shaft and convert it into an electrical signal, which is transmitted to the process control system. The inclusion of this device in automated systems ensures a higher level of accuracy in valve operation, thereby improving the efficiency of various industrial processes.

Components and Functionality

Limit switch boxes consist of several components, each contributing to their overall functionality. The main components include:

Housing: Typically made from durable materials such as aluminum, stainless steel, or engineering plastics, the housing protects internal components from harsh environmental conditions, including dust, moisture, and corrosive substances.

Cam Mechanism: This mechanism is attached to the actuator shaft and rotates as the valve moves. It is calibrated to trigger the switches or sensors at specified positions, allowing accurate feedback on the valve’s open or closed status.

Switches or Sensors: Depending on the application, the box may use mechanical limit switches or non-contact sensors like inductive or magnetic proximity sensors. These elements detect the cam's position, translating the physical movement of the actuator into an electrical signal.

Terminals and Wiring: Electrical connections transmit signals from the switches or sensors to the process control system, enabling communication with control devices such as programmable logic controllers (PLCs) or distributed control systems (DCS).

The configuration of the limit switch box can vary based on specific requirements, including the number of switches or sensors, the type of enclosure, and explosion-proof or weatherproof ratings.

Benefits of Using Limit Switch Boxes for Pneumatic Actuators

The integration of a limit switch box with a pneumatic actuator offers multiple advantages, especially in industries where safety, efficiency, and reliability are paramount. These benefits include:

Enhanced Safety: Limit switch boxes help in preventing accidents by providing immediate feedback on the valve’s position. In hazardous environments, such as chemical plants or offshore platforms, knowing whether a valve is open or closed can prevent potential accidents and equipment damage.

Improved Process Control: Accurate monitoring of valve positions ensures that automated systems operate within specified parameters. By using limit switch boxes, operators can maintain consistent process conditions, reduce variability, and avoid production downtime caused by valve misalignment.

Maintenance and Troubleshooting: Fault detection becomes simpler and quicker when limit switch boxes are used. Any deviation from the expected valve position can be immediately flagged, allowing maintenance teams to address issues before they escalate into major problems.

Durability and Reliability: With robust construction and various protection ratings available, limit switch boxes can endure harsh industrial conditions. The use of corrosion-resistant materials ensures long service life, while explosion-proof enclosures cater to high-risk environments.

Types of Limit Switch Boxes

Several types of limit switch boxes cater to different industrial requirements. These include:

Weatherproof Limit Switch Boxes: Designed to protect against dust and moisture, they are suitable for outdoor applications where exposure to the elements is a concern.

Explosion-Proof Limit Switch Boxes: Ideal for hazardous environments where flammable gases or dust may be present, these boxes are built to prevent any ignition that could result from electrical components.

Stainless Steel Limit Switch Boxes: Used in industries such as pharmaceuticals or food processing, where hygiene is a priority, stainless steel enclosures resist corrosion and ensure easy cleaning.

Compact Limit Switch Boxes: For applications with limited space, compact models provide the necessary functionality without occupying much room.

Installation and Calibration Considerations

To ensure optimal performance, proper installation and calibration of the limit switch box are essential. The box should be mounted securely on the actuator, and the cam mechanism needs to be aligned with the actuator shaft. Calibration should involve setting the switches or sensors to trigger at the correct valve positions, which typically requires adjusting the cam’s position.

Regular inspection and maintenance are recommended to maintain accuracy, especially in demanding industrial settings where frequent cycling of valves may occur. Periodic checks will ensure the limit switch box continues to provide reliable feedback and control.

Conclusion

Incorporating a limit switch box for a pneumatic actuator significantly enhances the automation, safety, and efficiency of industrial processes. By providing precise valve position feedback, these devices support better process control, reduce maintenance costs, and improve safety standards. For industries seeking reliable solutions for their automation needs, selecting the appropriate type of limit switch box is essential for ensuring long-term operational success.

When considering limit switch boxes, it is recommended to choose quality products that match the specific requirements of the application, ensuring reliable performance even in the most challenging environments.