In the world of engineering and industrial automation, precision and control are paramount. One essential component that plays a pivotal role in achieving this is the Rack & Pinion Actuator. This ingenious mechanical device has quietly revolutionized various industries, enabling precise motion control, reliable operation, and enhanced efficiency. In this article, we delve into the inner workings, applications, and benefits of Rack & Pinion Actuators.

Understanding Rack & Pinion Actuators

At its core, a Rack & Pinion Actuator is a mechanical system that translates rotary motion into linear motion. The mechanism consists of two main components: the rack, which is a linear gear-like component, and the pinion, a small gear that meshes with the rack. As the pinion rotates, it engages with the rack, converting the rotational force into a linear displacement.

Key Components and Mechanism

Rack: The rack is a toothed bar with a straight profile. Its teeth mesh with the teeth of the pinion gear, allowing for controlled linear movement.

Pinion: The pinion gear is attached to a rotary actuator, such as a motor or a hydraulic cylinder. When the pinion rotates, it engages with the rack, causing it to move along its linear path.

Applications Across Industries

Rack & Pinion Actuators find versatile applications across a wide range of industries, owing to their precision and reliability:

Industrial Automation: In manufacturing and assembly lines, these actuators are used to precisely position components, manipulate machinery, and control processes.

Valve Control: Rack & Pinion Actuators are extensively employed in the oil and gas, water treatment, and chemical industries to control the opening and closing of valves.

Automotive: They play a role in various automotive applications, such as steering systems, seat adjustments, and transmission control.

Aerospace: In aircraft and spacecraft, these actuators are essential for controlling flaps, landing gear, and other critical mechanisms.

Robotics: Rack & Pinion Actuators are integral to the movement and manipulation of robotic arms, enhancing their precision and range of motion.

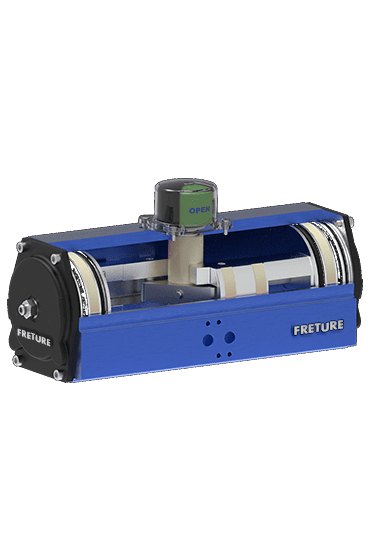

|

| Pneumatic Rack & Pinion Actuator |

Advantages of Rack & Pinion Actuators

Precision: The mechanical engagement between the rack and pinion ensures precise linear motion control, making them ideal for applications requiring accurate positioning.

Compact Design: Rack & Pinion Actuators are known for their compact size and efficient use of space, making them suitable for installations with limited room.

High Force Output: They offer high force output relative to their size, allowing them to handle heavy loads and demanding tasks.

Reliability: With fewer moving parts, these actuators are known for their durability and minimal maintenance requirements.

Cost-Effectiveness: Their robust design and longevity contribute to cost-effective operations over the long term.

Rack & Pinion Actuators stand as a testament to the brilliance of mechanical engineering, transforming rotary motion into precise linear movement across various industries. From manufacturing floors to outer space, these actuators play a silent but crucial role in enabling complex processes, enhancing control, and driving efficiency. As technology continues to advance, the humble Rack & Pinion Actuator continues to be a cornerstone of innovation, powering the machinery and mechanisms that shape our modern world.

No comments:

Post a Comment