In today’s rapidly evolving industrial landscape, automation is at the forefront of enhancing efficiency and productivity. Among the various components that play a critical role in automation, linear actuators—both electric and pneumatic—stand out for their significance in converting rotational motion into linear motion. This transition is essential across various industries, including manufacturing, packaging, and robotics. Understanding the fundamental aspects of these actuators provides insight into their application and the future of industrial processes.

What Are Linear Actuators?

Linear actuators are devices that create linear motion from a rotational source of power. They can be powered by various energy types, including electric current or compressed air, giving rise to two main categories: electric and pneumatic actuators. Each type has its specific advantages and applications, making them integral to numerous industrial systems.

Electric Linear Actuators

Electric linear actuators utilize electrical energy to produce linear movement. These actuators often feature a motor, which drives a screw or a belt mechanism, enabling precise control of the motion. Electric actuators are known for their accuracy and control, making them ideal for applications requiring exact positioning. They are commonly used in environments where precision and repeatability are essential, such as CNC machines, robotic arms, and medical devices.

Benefits of Electric Linear Actuators:

- Precision and Control: With advanced control systems, electric actuators can achieve high levels of positioning accuracy.

- Energy Efficiency: Electric actuators generally consume less energy compared to their pneumatic counterparts, especially during idle times.

- Low Maintenance: They typically have fewer moving parts and require less maintenance, reducing downtime.

- Environmentally Friendly: Being electrically powered, they have a lower environmental impact than pneumatic systems, which may rely on compressed air.

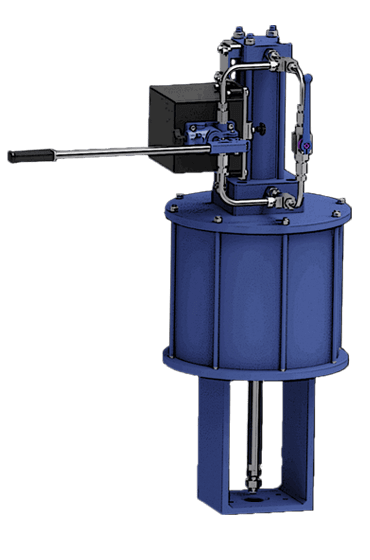

- Pneumatic Linear Actuators

- Pneumatic linear actuators use compressed air to create movement. The air pressure forces a piston within a cylinder to move, generating linear motion. These actuators are particularly favored in environments that require rapid motion and high force applications, such as material handling and assembly lines.

Benefits of Pneumatic Linear Actuators:

- High Speed and Force: Pneumatic actuators can deliver quick and powerful strokes, making them suitable for fast-paced production lines.

- Simplicity and Reliability: The straightforward design of pneumatic systems allows for reliable operation in demanding environments.

- Robust and Durable: Designed to withstand harsh conditions, pneumatic actuators can operate effectively in environments with dust, debris, or high temperatures.

Choosing the Right Actuator

The decision between electric and pneumatic linear actuators hinges on specific application requirements. Factors such as speed, force, precision, and operational environment must be carefully considered. For instance, if an application demands rapid movement and high power, a pneumatic actuator might be the best choice. Conversely, for applications that require precision and repeatability, electric linear actuators would likely excel.

Another consideration is the cost of operation and maintenance. Electric actuators may initially be more expensive but can provide long-term savings through energy efficiency and reduced maintenance needs. On the other hand, pneumatic actuators might be less expensive upfront but could incur higher ongoing costs due to energy consumption and maintenance.

The Future of Linear Actuators in Industry

As industries continue to embrace automation, the demand for effective linear actuators is set to rise. Innovations in technology are driving improvements in actuator performance, making them more intelligent and interconnected. The integration of smart technologies and IoT connectivity is allowing for real-time monitoring, predictive maintenance, and enhanced control, significantly increasing the efficiency of industrial operations.

Moreover, advancements in materials and designs are making both electric and pneumatic actuators more compact and lighter without compromising power or performance. This transformation facilitates more versatile applications in industries ranging from manufacturing to the automotive sector and beyond.

In conclusion, industrial electric and pneumatic linear actuators play a crucial role in the automation landscape, each offering distinct advantages that cater to various industry needs. As technology continues to advance, the capabilities and applications of these actuators will only expand, driving further innovations in automation. For those seeking reliable and efficient solutions, Freture Techno stands out as one of the leading industrial electric Linear actuator manufacturers in India, committed to delivering high-quality products that enhance operational efficiency and precision across diverse industries. With a focus on innovation, Freture Techno is positioned to meet the evolving demands of the industrial sector, ensuring that businesses can harness the full potential of automation.

No comments:

Post a Comment