In today’s highly competitive industrial environment, the demand for precision, reliability, and operational efficiency is paramount. Manual valve operation is increasingly being replaced by automated valve systems to reduce downtime, enhance safety, and improve process control. At the heart of these systems lies a range of actuators and accessories designed to automate valves across industries such as oil & gas, water treatment, chemicals, pharmaceuticals, and power generation.

|

| Valve Automation Actuators |

This article explores the key components in valve automation, including Rotary Actuators, Rack & Pinion Actuators, Scotch & Yoke Actuators, Linear Actuators, Diaphragm Actuators, Limit Switch Boxes, and Local Control Stations, and their roles in modern industrial applications.

🔄 What is Valve Automation?

Valve automation refers to the process of using mechanical devices (actuators) to open, close, or modulate valves without manual intervention. These actuators may be powered by electric, pneumatic, or hydraulic sources and can be integrated with control systems for remote operation or automatic response based on process parameters.

🔧 1. Rotary Actuator

A Rotary Actuator converts energy into rotational motion, typically used to automate quarter-turn valves like ball, butterfly, or plug valves. They offer a simple and compact design, fast response time, and minimal maintenance.

Key Features:

-

90° rotation for on/off operation

-

Compact design for tight installations

-

Suitable for high-speed applications

-

Available in pneumatic, electric, and hydraulic versions

Applications: Water distribution, oil pipelines, HVAC, food and beverage industries

⚙️ 2. Rack & Pinion Actuator

The Rack & Pinion Actuator is a subtype of rotary actuator that uses a rack (linear gear) and pinion (circular gear) to produce torque. It is especially favored for its symmetrical torque distribution and high-speed performance.

Advantages:

-

Precise, repeatable operation

-

Lightweight and cost-effective

-

Double-acting and spring-return models available

-

Easy to mount on ISO-compliant valves

Applications: Chemical dosing systems, batch processing, and high-cycle valve operation

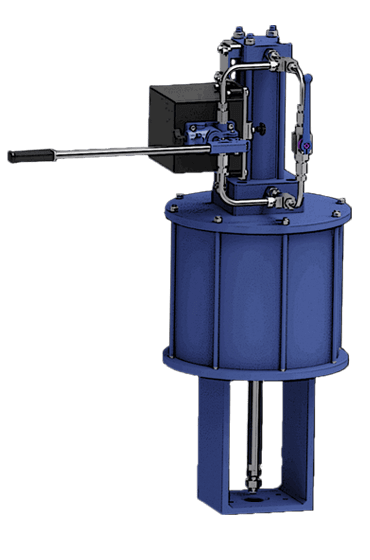

🔁 3. Scotch & Yoke Actuator

A Scotch & Yoke Actuator is designed for high-torque applications, utilizing a yoke mechanism to convert linear motion into rotary motion. It is often used where heavy-duty or large-diameter valves need to be actuated.

Why Choose Scotch & Yoke:

-

Higher torque at the start and end of the stroke

-

Ideal for valves with tight shut-off requirements

-

Available in pneumatic and hydraulic variants

Industries Used: Oil & gas, mining, power plants, and petrochemicals

↕️ 4. Linear Actuator

Unlike rotary actuators, Linear Actuators provide straight-line (linear) movement, commonly used with gate valves, globe valves, and diaphragm valves. These actuators can be electrically or pneumatically driven.

Key Benefits:

-

Smooth linear motion for modulating control

-

Accurate flow regulation

-

Suited for large-size valves and dampers

Common Applications: Power generation, water treatment, and process control systems

🌬️ 5. Diaphragm Actuator

Diaphragm Actuators are a form of linear actuator that uses air pressure acting on a diaphragm to create motion. They are highly reliable for modulating control and fail-safe shut-off in critical processes.

Features:

-

Fast response and low hysteresis

-

No leakage due to sealed design

-

Commonly used in control valves

Best For: Precision control in pharmaceutical, chemical, and HVAC systems

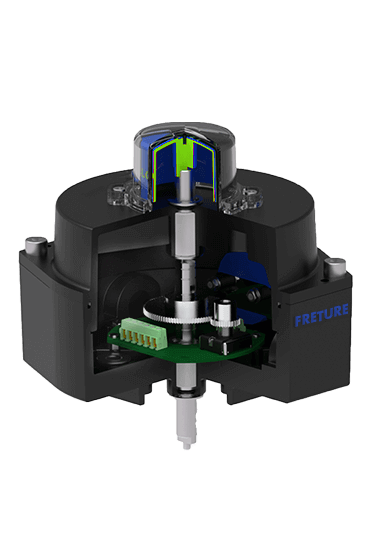

📦 6. Limit Switch Box

A Limit Switch Box is an essential accessory in valve automation that indicates the open or closed position of a valve. These are often used with PLC systems for remote monitoring.

Why It Matters:

-

Provides valve status feedback

-

Helps in diagnostic and safety logic

-

Available in weatherproof, flameproof, and explosion-proof designs

Application Fields: Refineries, water plants, and hazardous area operations

🕹️ 7. Local Control Station (LCS)

The Local Control Station is an operator interface placed near the valve actuator, allowing manual override or control during maintenance or emergencies. It includes switches, indicators, and sometimes a display unit.

Highlights:

-

Offers local operation and monitoring

-

Emergency shut-down capability

-

Improves system flexibility and safety

Industries Benefiting: Oil & gas, power, marine, and offshore installations

⚙️ Integration with Control Systems

Valve automation systems are often integrated into SCADA, DCS, or PLC systems for remote control and real-time monitoring. Advanced actuators also come with feedback sensors, modulating control options, and smart diagnostics for predictive maintenance.

✅ Benefits of Valve Automation

-

Improved Efficiency: Fast, accurate, and repeatable valve operation

-

Enhanced Safety: Reduces human intervention in hazardous areas

-

Lower Operational Costs: Reduced downtime and maintenance

-

Remote Monitoring: Real-time data and diagnostics

-

Precise Control: Ideal for process modulation and flow regulation

🏭 Industries Using Valve Automation

-

Oil & Gas

-

Chemical & Petrochemical

-

Water & Wastewater Treatment

-

Pharmaceuticals

-

Power Generation

-

Food & Beverage

-

Pulp & Paper

Conclusion

Valve automation Actuators has transformed process control by offering faster response times, increased accuracy, and reduced manual intervention. Whether you require a robust Scotch & Yoke actuator for a large pipeline valve or a limit switch box to monitor valve status, the right automation solution can significantly enhance operational reliability.

Manufacturers and plant engineers must carefully evaluate their application needs—including torque, speed, environmental conditions, and control strategy—before selecting actuators and accessories. Choosing high-quality, industrial-grade components ensures long-term performance, safety, and compliance with international standards.